Hannah Wenzlick

Aerospace Engineering Portfolio

About Me

I’m currently pursuing my B.S. in Aerospace Engineering at the University of Cincinnati, with minors in Astrophysics and Mathematics. What drives me most is building; I’m passionate about taking an idea from a sketch to a fully machined prototype that solves real-world problems.

Through my previous internships, I’ve learned to thrive in environments where I can work hands-on. Some of my proudest moments have come from designing, modeling, and machining precision aerospace-grade components that saved associates hours of work and helped the company reduce unnecessary costs.

I’m also eager to connect data to real-world decisions. When complex company-wide issues arise, I know how to lean into my coding and analytical skills to break the problem down, test ideas, and collaborate with experienced engineers to arrive at the best solution. I enjoy bridging the gap between data, engineering intuition, and practical outcomes.

I love tackling problems head-on and the process of transforming raw concepts into working prototypes. At my core, I’m a builder, a problem solver, and someone who learns best by doing, especially when the work makes a positive and impactful difference for others.

Experience

NMG Aerospace: Manufacturing Engineering Co-op

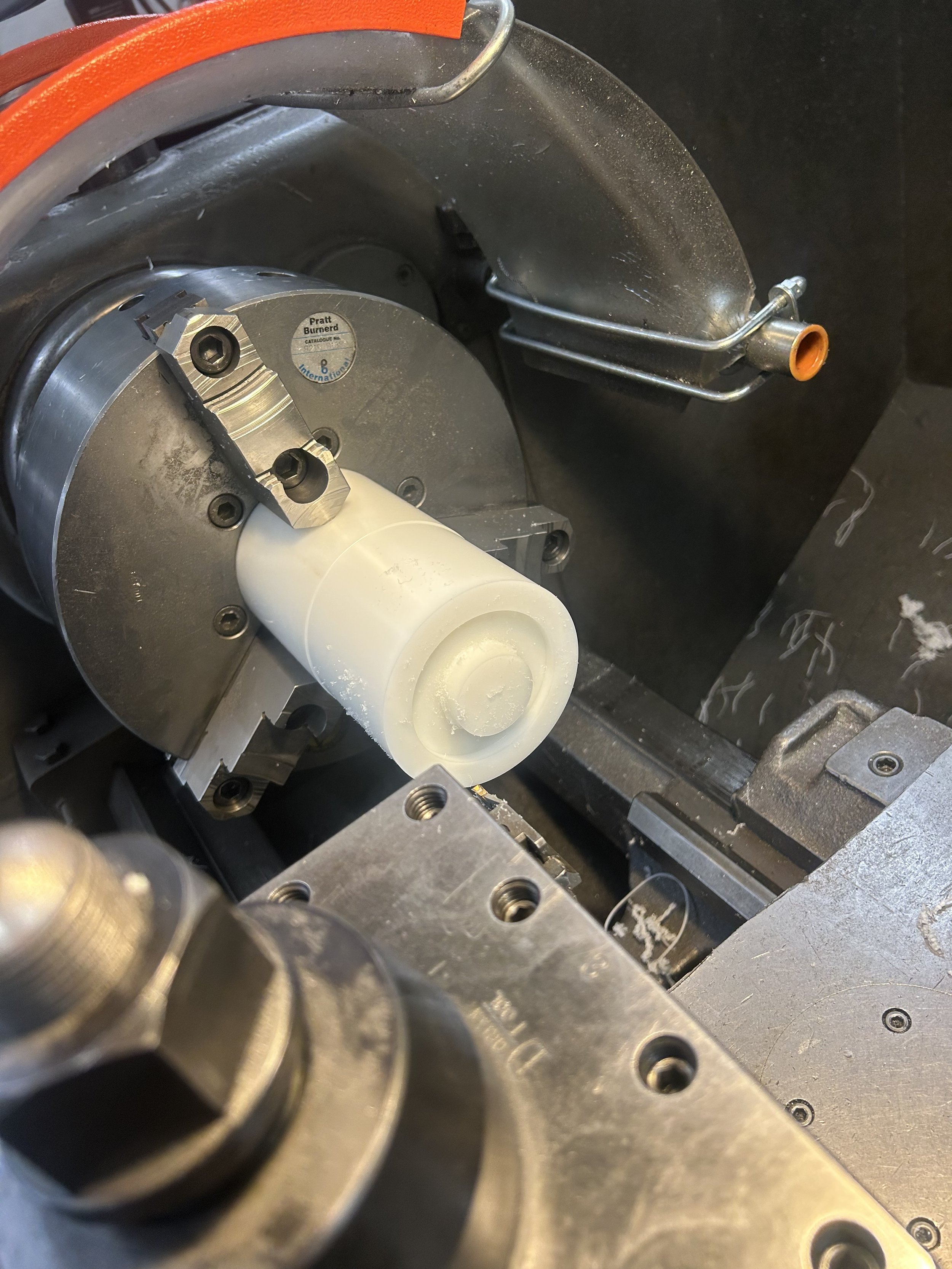

• Prototyped 20+ custom precision tools and fixtures using mills, lathes, welding equipment, and manual machining techniques, saving over $15,000 in outsourced manufacturing costs.

• Led a data-driven investigation into hydraulic actuator failures with major clients (Lockheed Martin, Collins Aerospace, etc.), analyzing 4+ years of production data to ultimately conclude the best solution.

• Improved 15+ Standard Operating Procedures (SOPs) by observing processes, identifying inefficiencies, and implemented revisions through real time hands-on discussion.

Honda - Engine Systems Manufacturer

• Assembled 10,000+ internal combustion engines, consistently installing critical components with critical components within tight tolerance specifications to ensure engine performance and reliability.

• Communicated with 30+ people on a multi-stage production team, maintaining clear communication to ensure seamless workflow continuity, reduce downtime, and meet production goals.

• Excelled in a high pressure, fast-paced environment, developing detail-oriented awareness and the ability to adapt quickly while maintaining tight tolerance production standards.

Miller Precision Mfg. - Metal Manufacturing

• Identified and implemented targeted process improvements that reduced daily defects by 80%, decreasing errors from 100 parts to < 20 parts per day, strengthening efficiency and product quality.

• Disassembled and repaired malfunctioning CNC lathes, as well as delving into the M-code to restore functionality and minimize equipment downtime to sustain production output.

• Spearheaded the manufacturing of 15+ new customer products, supporting management’s cross functionality and minimize equipment downtime to sustain production output.

Projects

Click on each one to learn more!

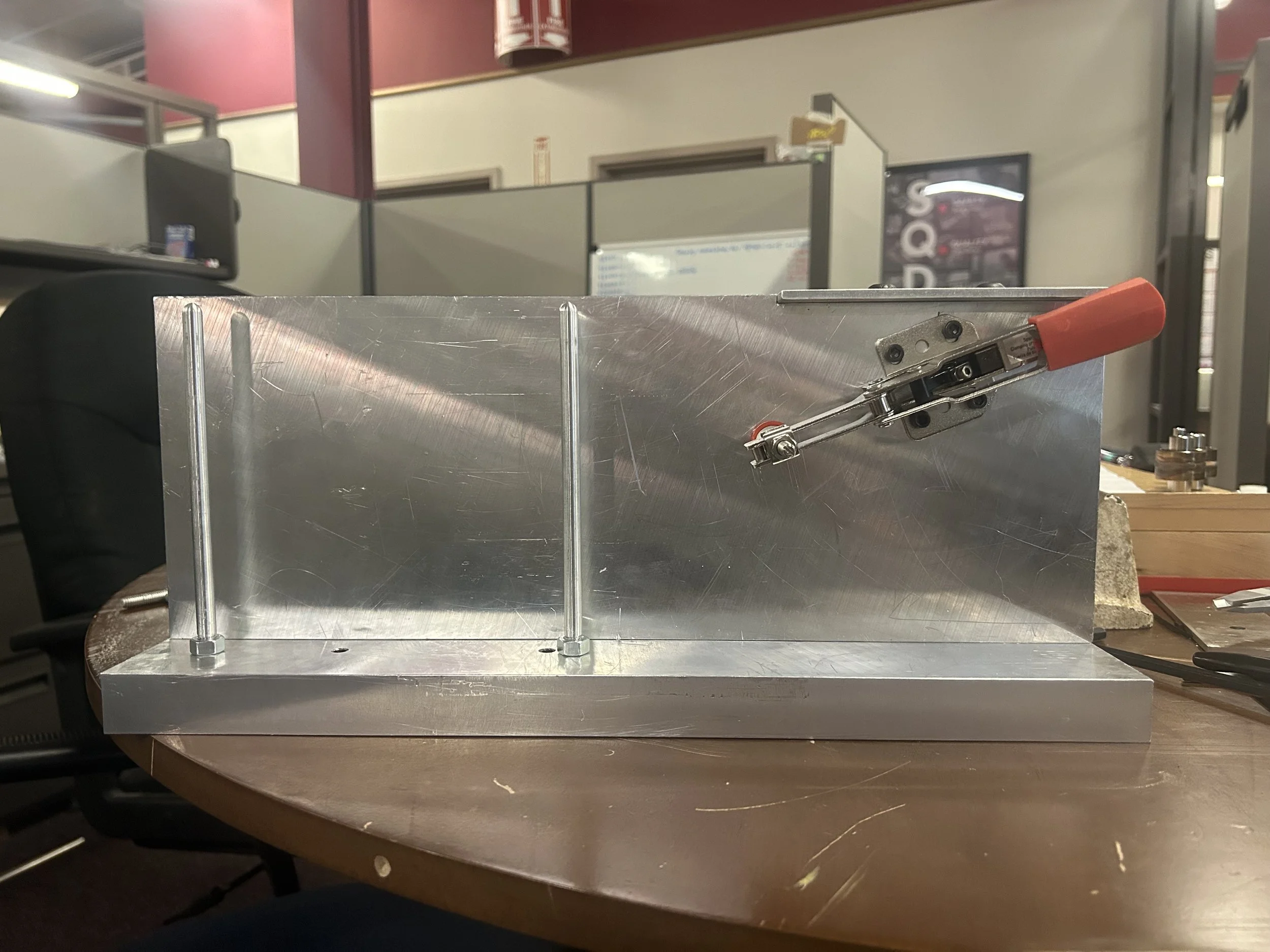

Drain Mast Forming Clamp

Hydraulic Actuator Data Integrity Analysis

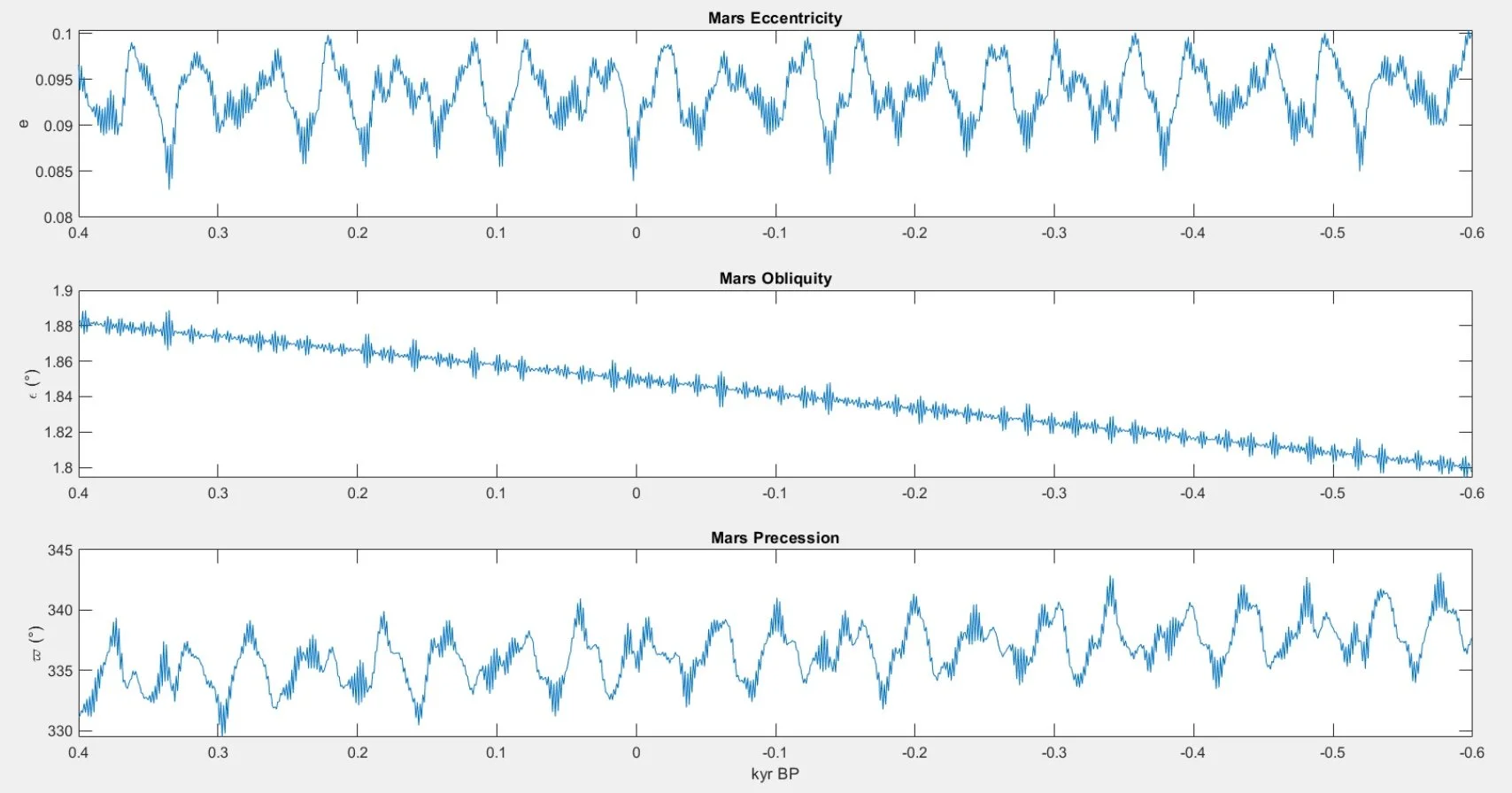

Mars Milankovitch Cycle Simulation

Raspberry Pi Arcade Table

IR-Activated LED Interactive Table

Swage & Proof Load Tool

Gravitational Simulation

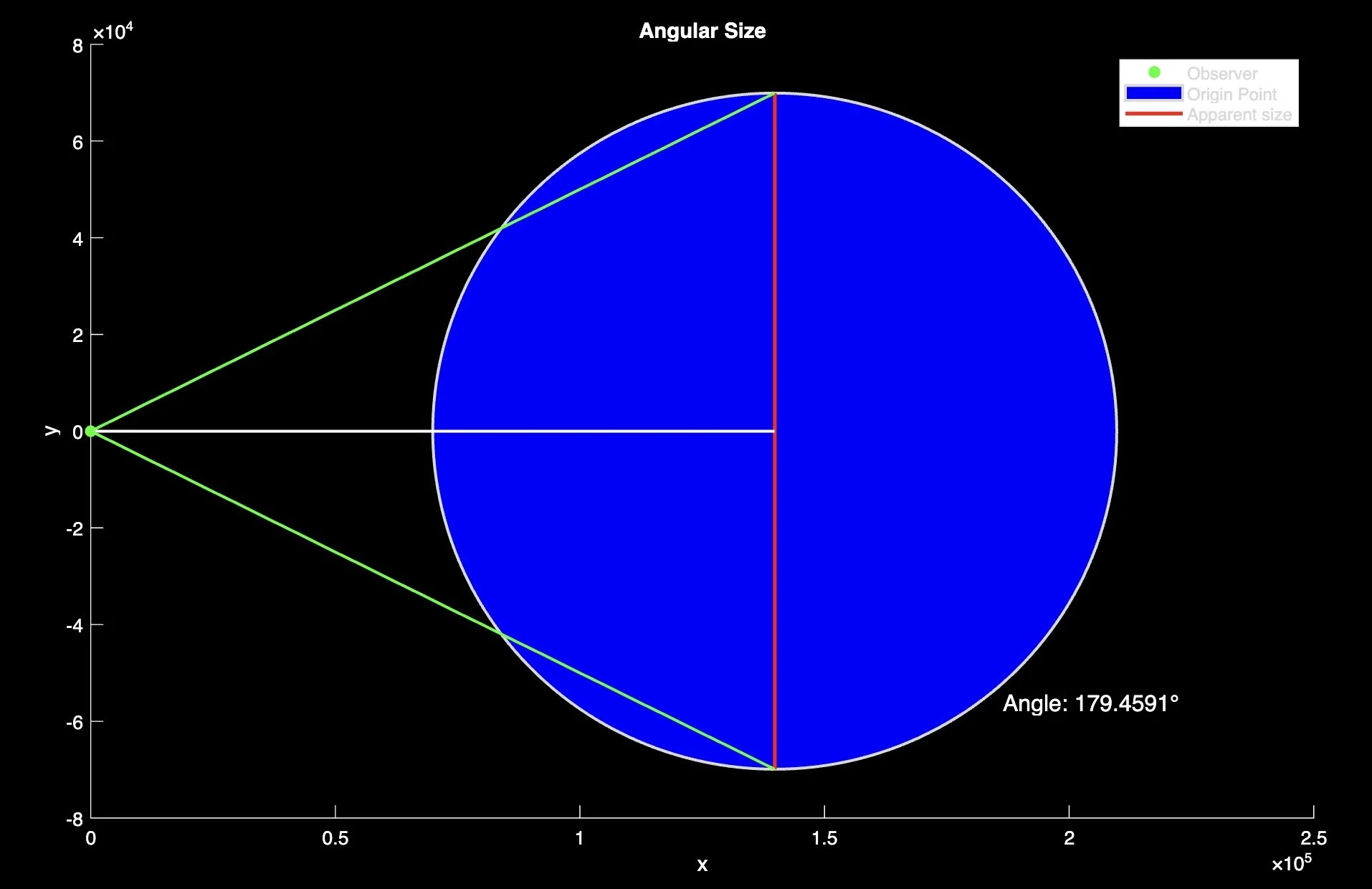

Parallax Simulation

Thermal Spark Arrestor

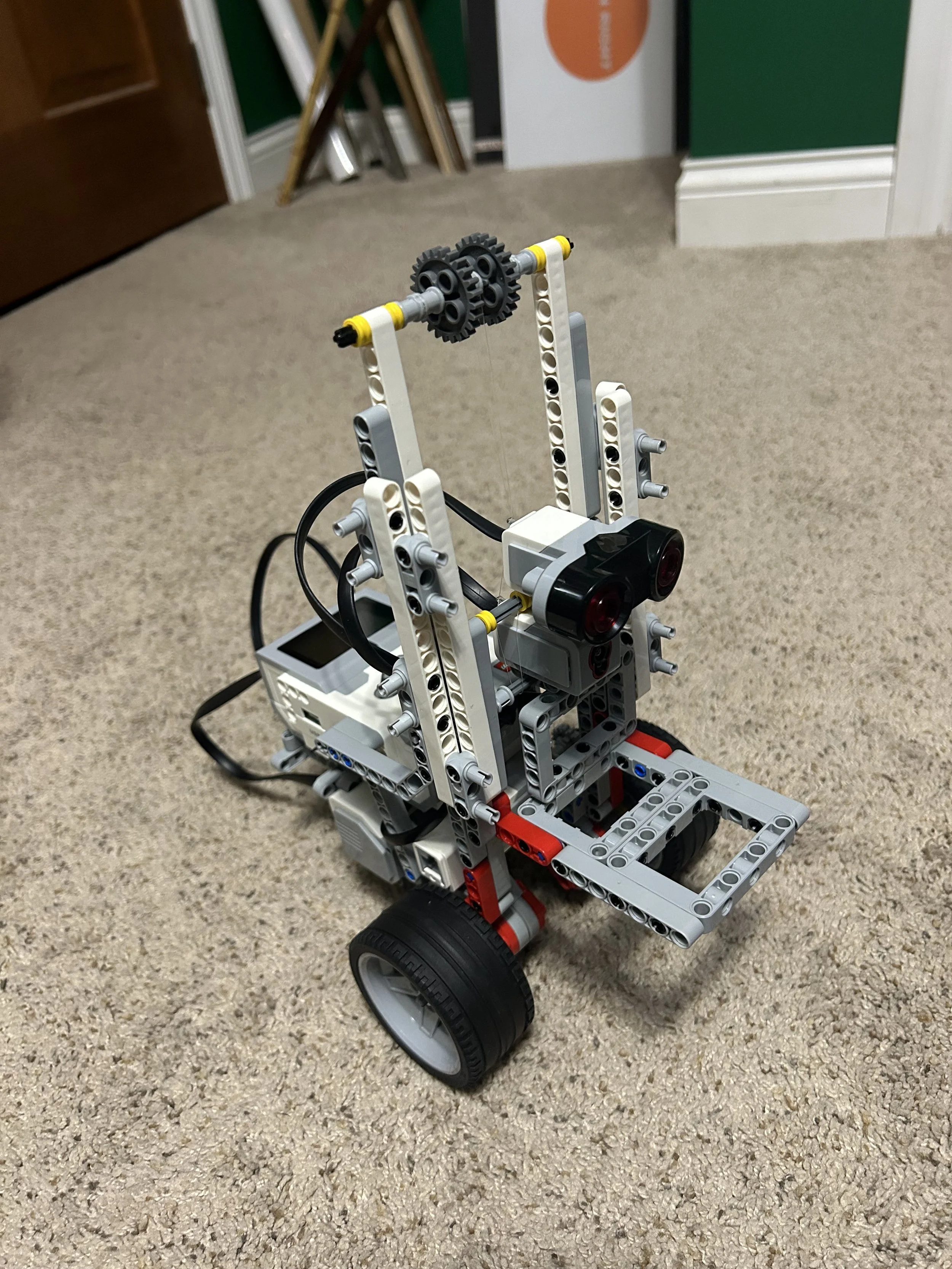

Autonomous Multi-Terrain Robot

Spherical Bearing Housing Torque Fixture